Size Range

From small to large, meeting the needs

of various fixed-wing UAVs

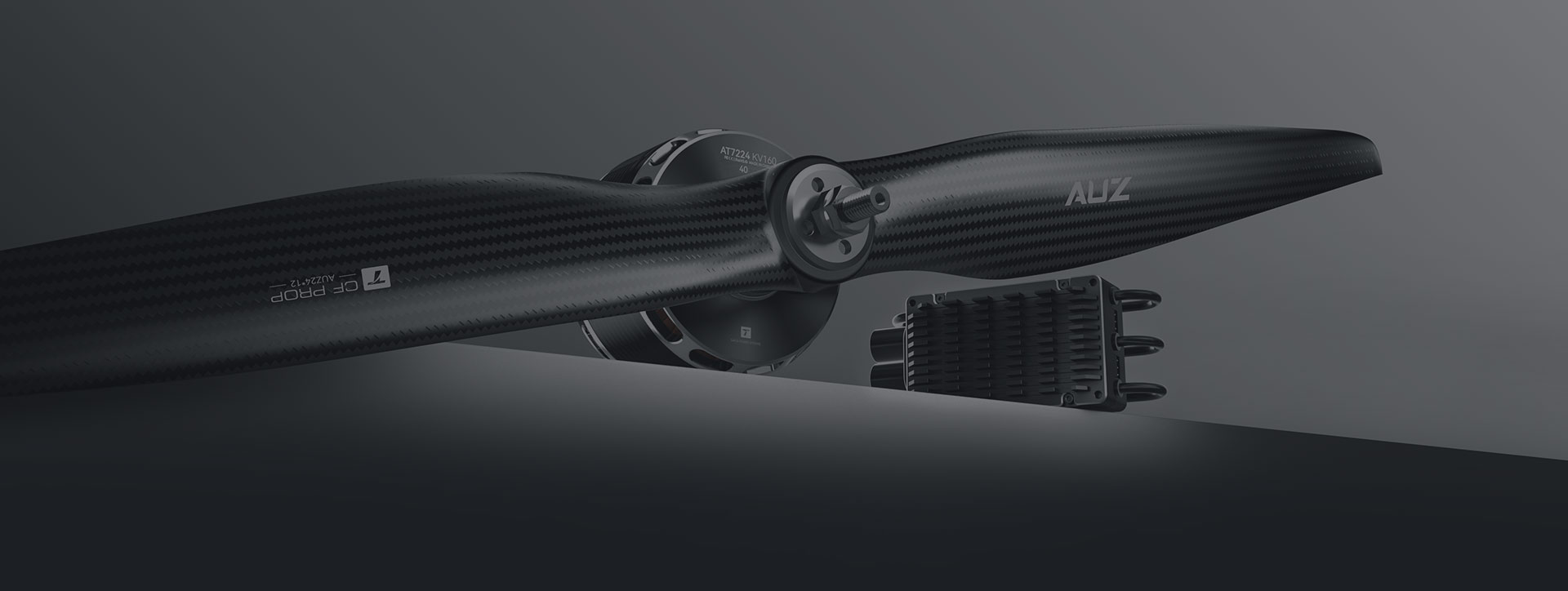

AUZ Series

-Electric Fixed-Wing

Propellers

recisely matched with AT motors for both powerful performance and extended endurance. Compatible with all layouts and available in multiple sizes

High-Efficiency

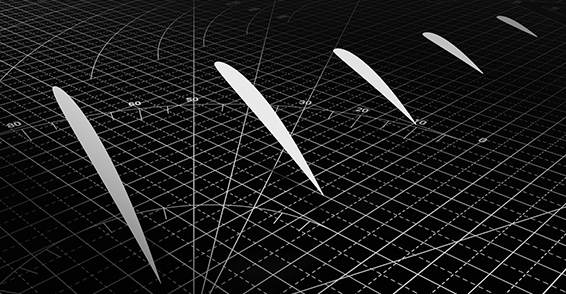

Aerodynamic Design

Airfoils specifically developed for electric fixed-wing UAVs, enhancing aerodynamic efficiency while reducing noise

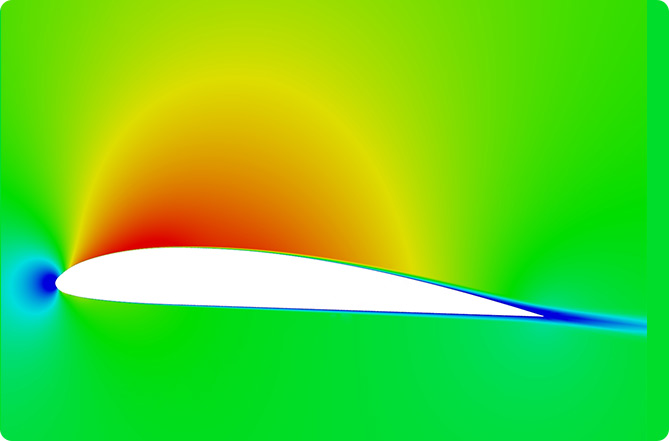

Dedicated Airfoil Design

Optimized airfoil profiles for electric fixed-wing UAVs

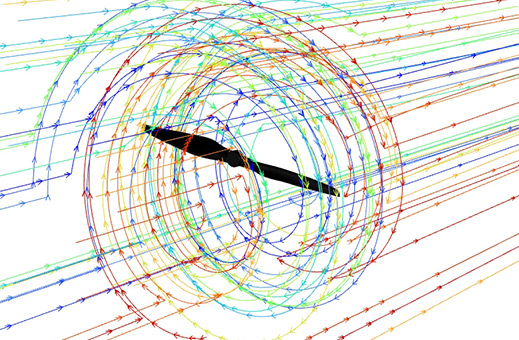

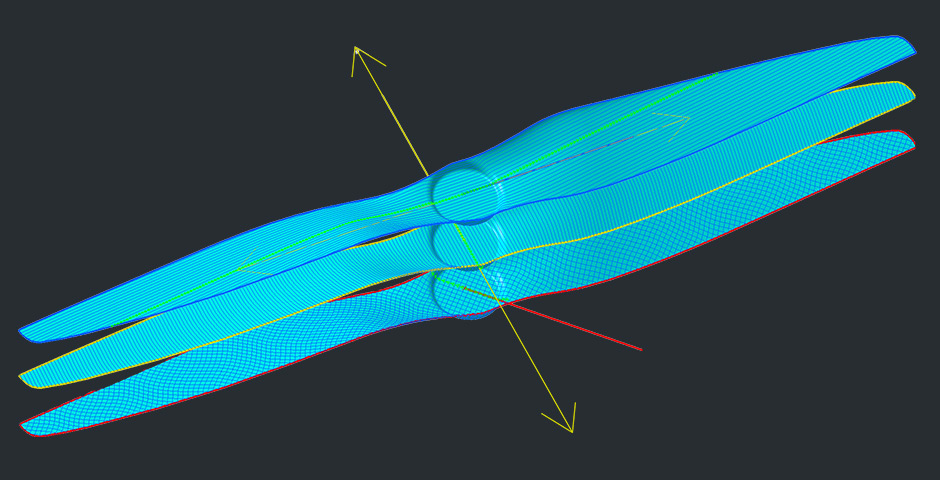

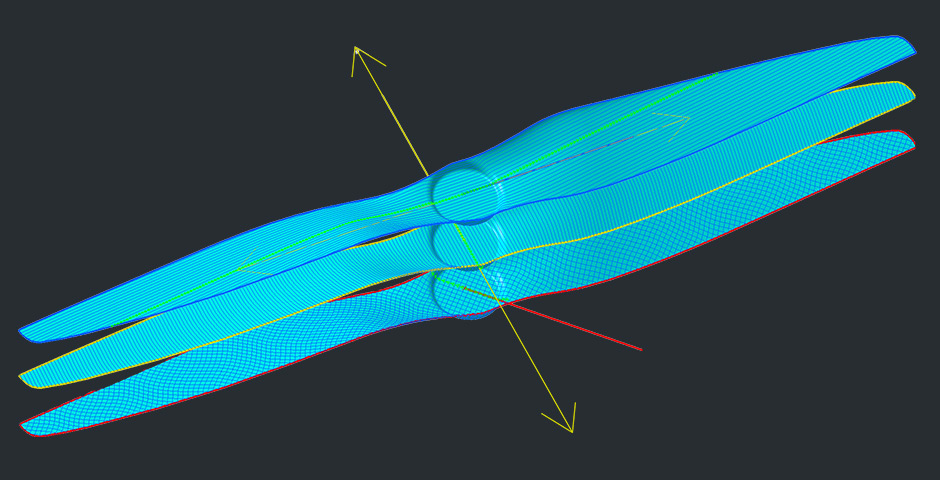

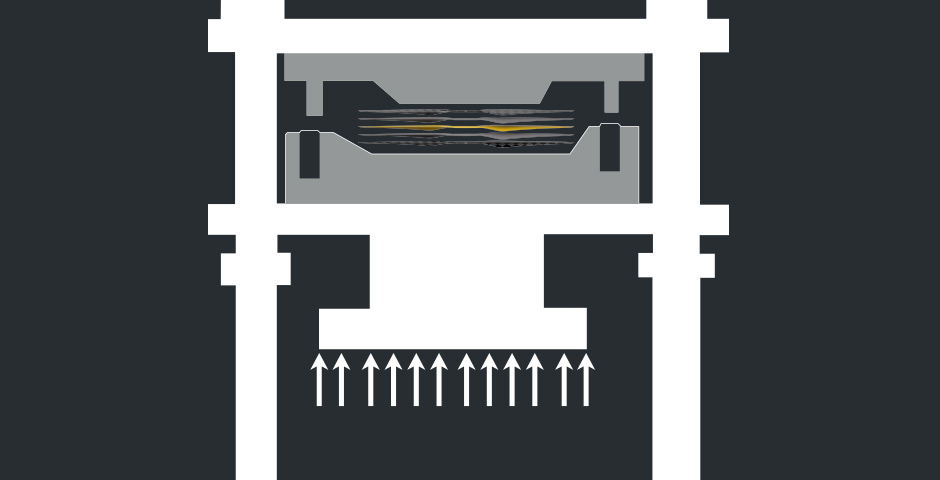

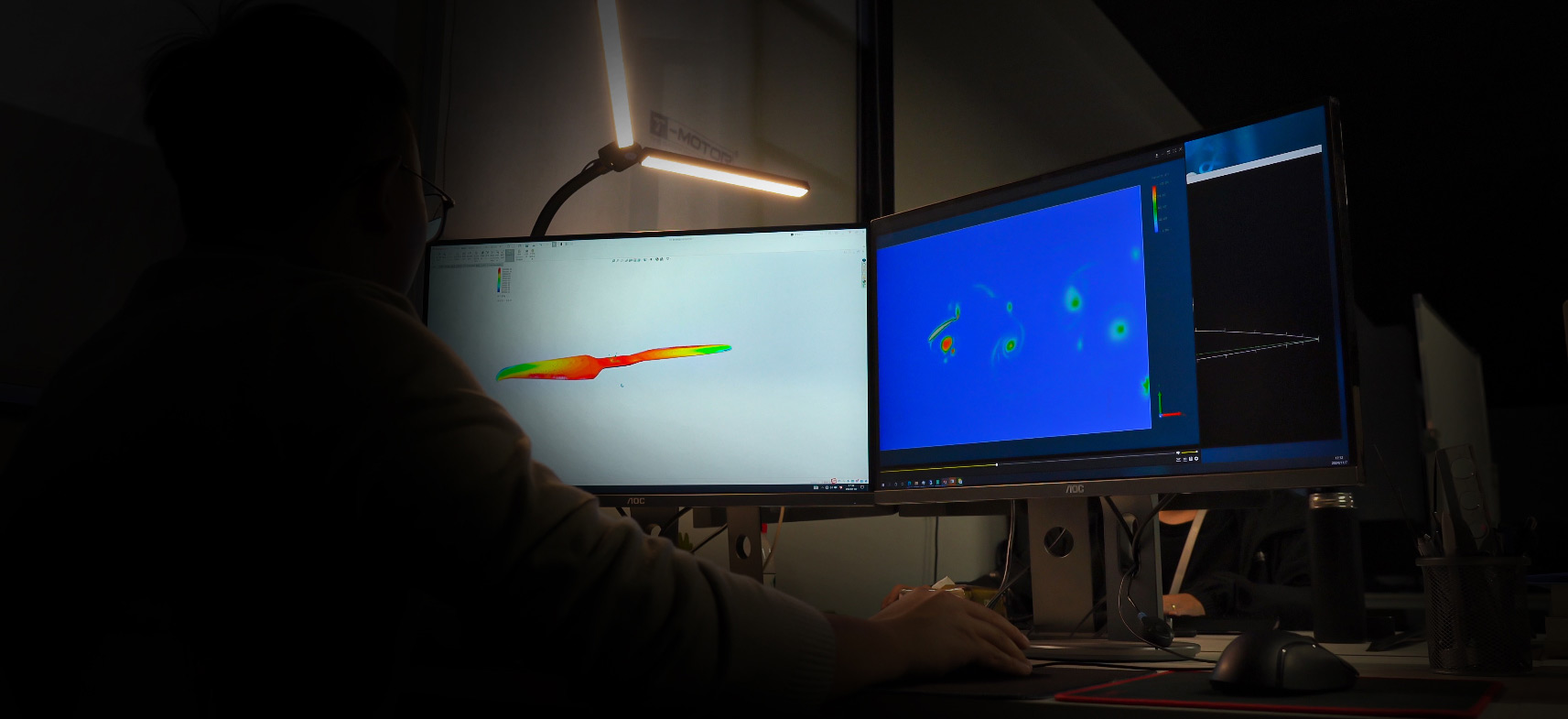

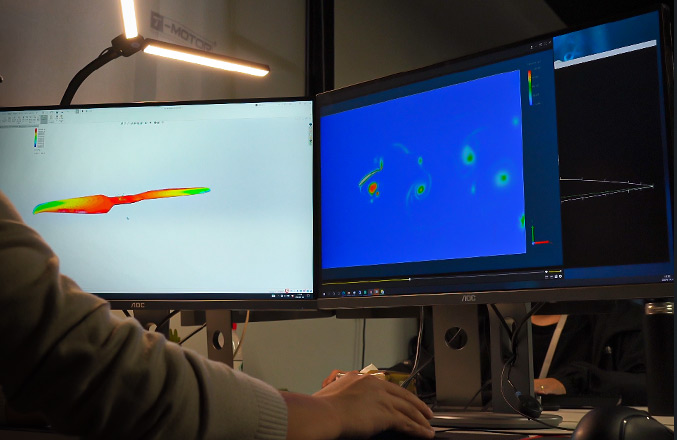

CFD Simulation Verification

Detailed flow field analysis down to individual profiles

optimizing aerodynamic performance at every section

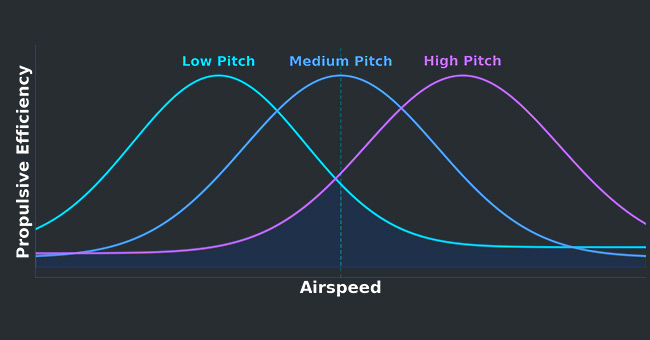

Forward Flight Efficiency Optimization

The entire AUZ series offers multiple pitch options with each variant optimized for a specific speed range Select based on your flight envelope for high-efficiency output within the target speed interval enabling more power-efficient cruising

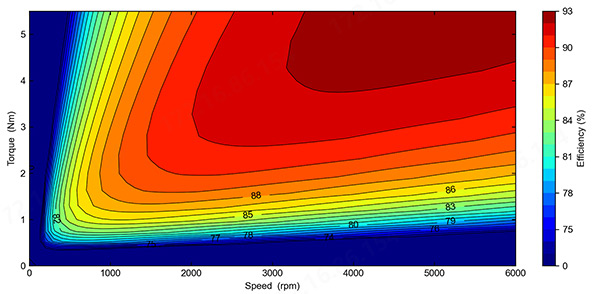

Precision Power Matching

Optimized chord length and

angle of attack combination + AT motor RPM/

torque characteristics = Improved overall

power system efficiency

consumption

duration

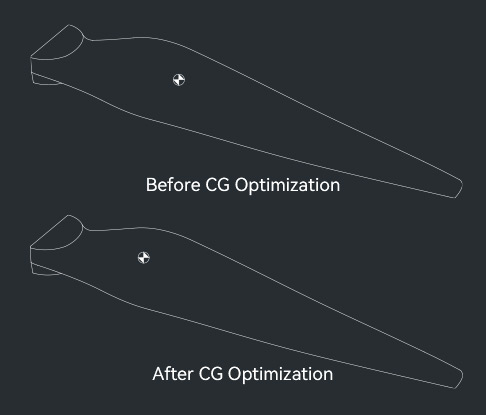

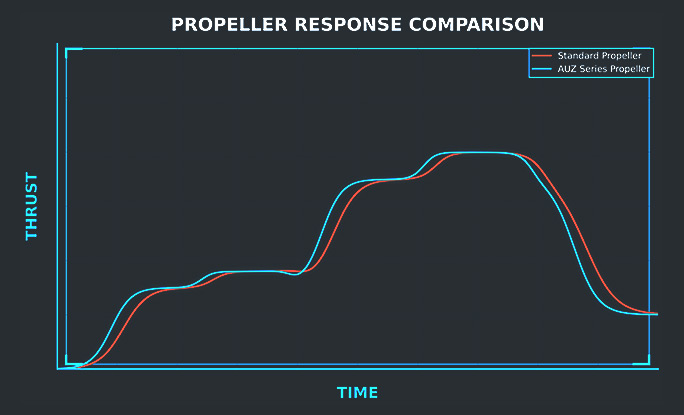

Rapid Dynamic Response

Optimized center of gravity distribution and reduced rotational inertia enhance acceleration and deceleration response, enabling more precise flight control

Optimized center of gravity for balanced mass distribution

Reduced rotational inertia for faster response

Enhanced acceleration and deceleration for quick bi-directional response

Precise flight control for an improved piloting experience

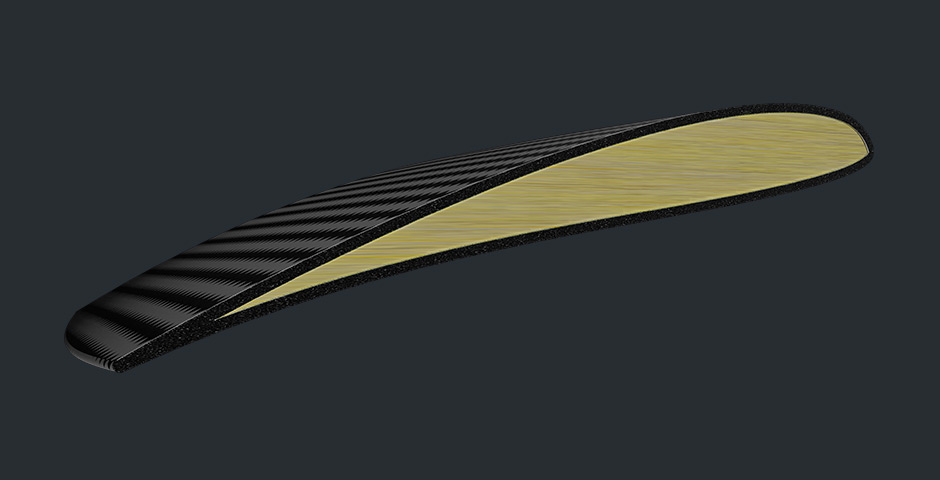

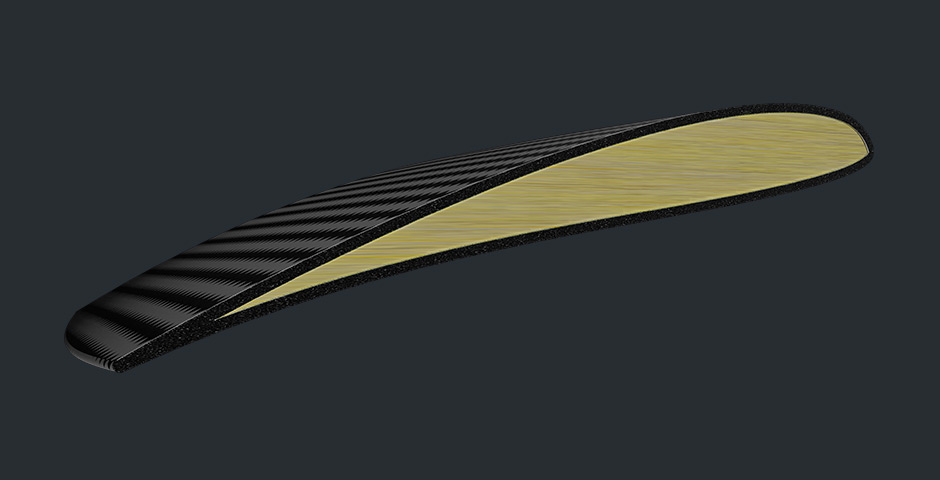

Stronger, Stiffer Structure

Layup design tailored for fixed-wing flight conditions. Adoption of prepreg + PMI core + molded one-piece forming process to achieve an optimal balance of "lightweight + high stiffness + high strength” for deformation resistance and service life extension

Bending & Torsion Resistant Layup Design

Optimized fiber orientation and ratio maximize strength and stiffness

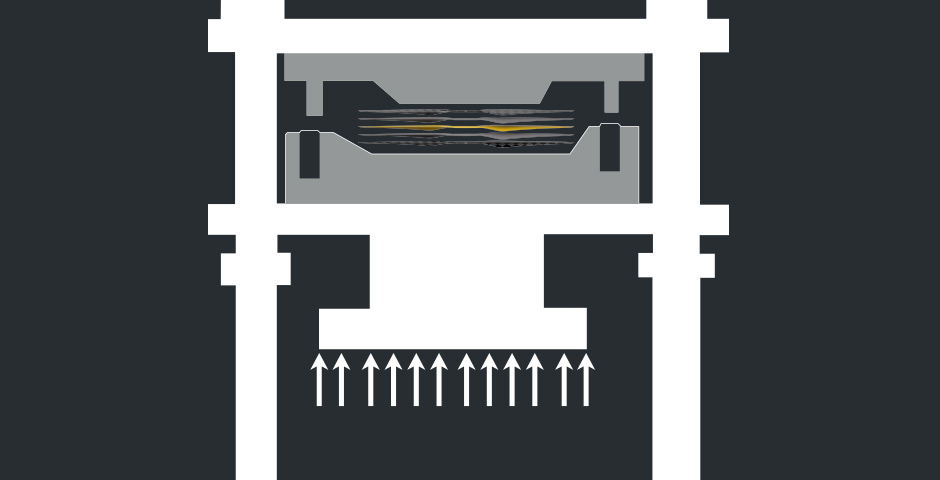

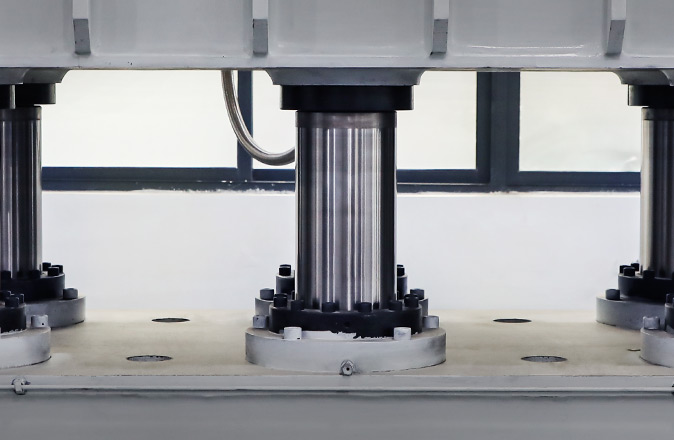

Prepreg Compression Molding for Integrated Forming

Product porosity below 1%, ensuring stable and reliable quality

PMI Foam Core

Lightweight, high-strength core material effectively increases stiffness while controlling total weight

Multi-Environment Adaptability

Premium materials and processes ensure stable performance and extended service life in harsh environments including high/low temperatures, humidity, salt spray, and UV exposure

Wide Temperature

Range Operation

Exceptional performance at all times

from extreme cold to scorching heat

Moisture & Humidity Resistance

Salt Spray Protection

UV Resistance

Multi-Layout Compatibility

Compatible with conventional layouts, flying wings, VTOLs, and other fixed-wing UAVs. One propeller adapts to multiple scenarios, covering mainstream applications like surveying, logistics and inspection

Conventional Layout

Flying Wing Layout

VTOL

Main Application Scenarios

Covers UAV needs across various industries

Surveying &

Mapping

Logistics &

Delivery

Power Line

Inspection

Agricultural Plant

Protection

Emergency

Response

Security &

Surveillance

Broad Customization Service

Sizes range from 12 to 34 inches. Supports custom pitch and speed optimization for precise matching with diverse mission requirements

Size Range

From small to large, meeting the needs

of various fixed-wing UAVs

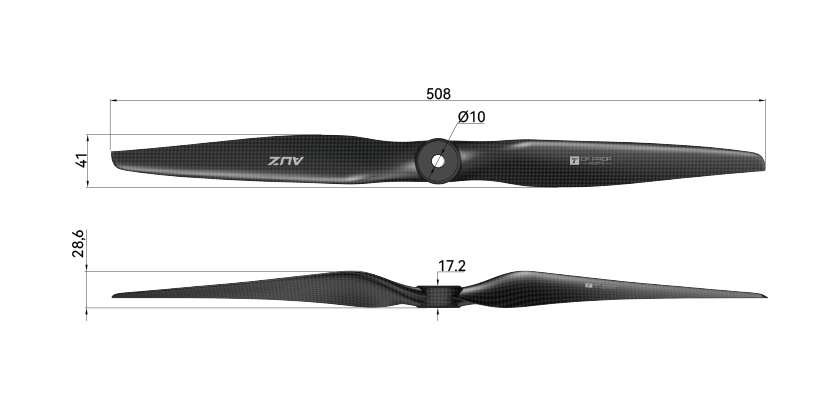

| Diameter(Inch) | 20 (508mm) | Material | Resin-based Carbon Fiber Composite + PMI Foam Core |

| Pitch(Inch) | 13 (330.2mm) | Surface Treatment | Matte |

| Average Single Blade Weight(g) | 50 | Type | Carbon Fiber Straight Propellers |

| Recommended Max RPM | 8650 | Application | Fixed-Wing UAV Propellers |

| Recommended Max Thrust(kg) | 16 | Connections & Dimensions | Ø10mm motor shaft central locking |

| Limit RPM(RPM) | 9500 | Recommendations | Recommended Solution: AT5230/AT5330/AT7215+AUZ20*13 |

| Limit Thrust(kg) | 20 |

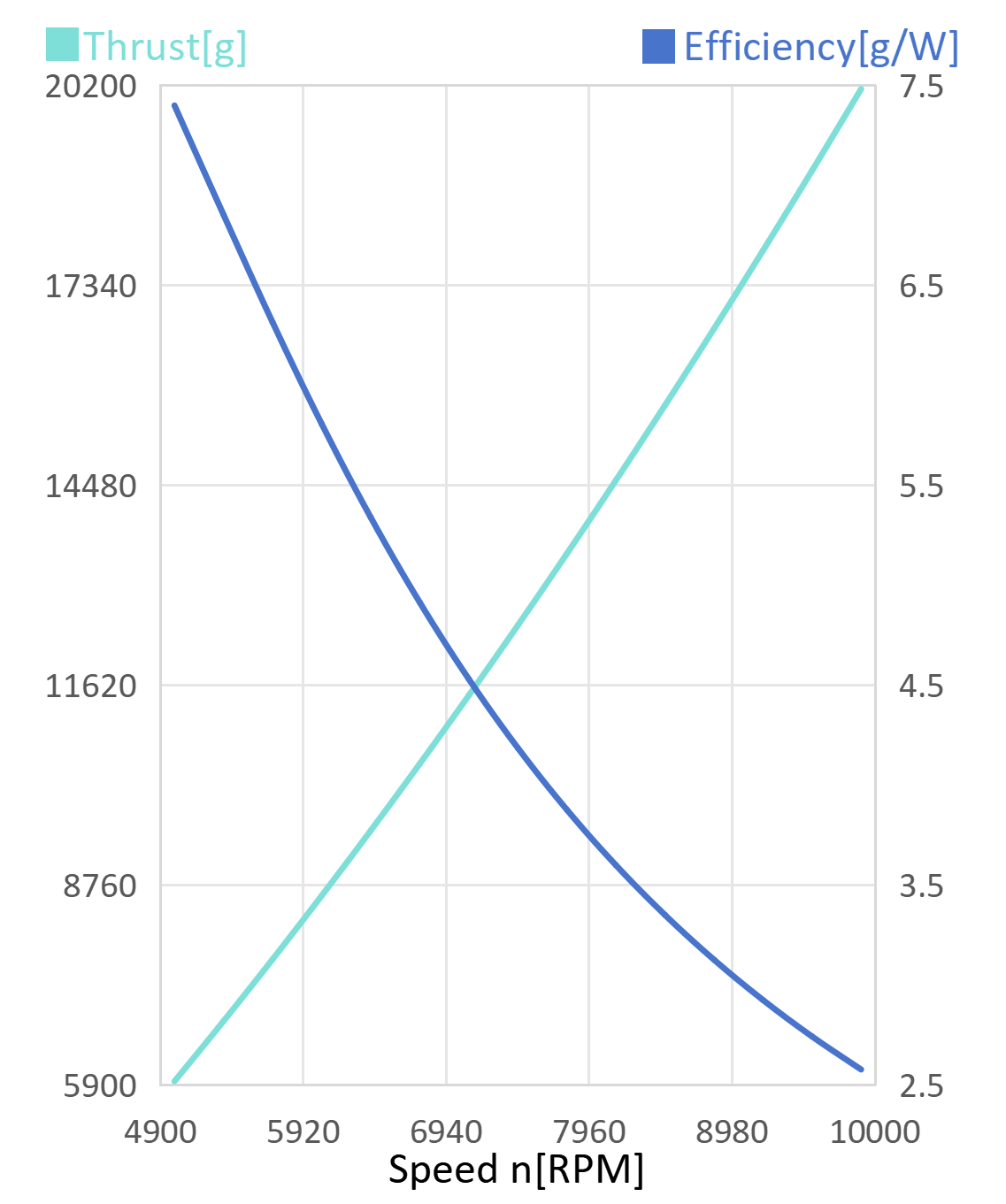

| Ambient Temperature: 22℃ Altitude: 25m | RPM | Torque (N·m) | Recommended Thrust (gf) | Output Power (W) | Effciency (gf/W) | |||

| 5000 | 1.54 | 5958 | 805.37 | 7.40 | |||

| 5350 | 1.78 | 6819 | 995.20 | 6.85 | ||||

| 5700 | 2.04 | 7703 | 1219.94 | 6.31 | ||||

| 6050 | 2.34 | 8611 | 1482.80 | 5.81 | ||||

| 6400 | 2.67 | 9542 | 1787.00 | 5.34 | ||||

| 6750 | 3.02 | 10496 | 2135.74 | 4.91 | ||||

| 7100 | 3.41 | 11474 | 2532.24 | 4.53 | ||||

| 7450 | 3.82 | 12476 | 2979.71 | 4.19 | ||||

| 7800 | 4.26 | 13501 | 3481.37 | 3.88 | ||||

| 8150 | 4.73 | 14549 | 4040.43 | 3.60 | ||||

| 8500 | 5.24 | 15621 | 4660.10 | 3.35 | ||||

| 8850 | 5.77 | 16717 | 5343.60 | 3.13 | ||||

| 9200 | 6.33 | 17835 | 6094.14 | 2.93 | ||||

| 9550 | 6.91 | 18978 | 6914.94 | 2.74 | ||||

| 9900 | 7.53 | 20143 | 7809.19 | 2.58 | ||||

| Important Notes | ||||||||

| Data may vary under different testing standards due to factors such as equipment, methodology, and environment. Ensure compatibility between the propeller mounting holes and motors. Refer to the drawing above for details. | ||||||||

1.The propeller is made of robust, high-strength material. If it contacts unprotected body parts while rotating at high speed, it can cause severe injury. Operate with extreme caution.

2.The structural strength has been thoroughly tested. Use within the recommended maximum thrust limit. Exceeding this limit may damage the blades. Do not test blade strength by bending them by hand, as this does not reflect actual flight forces and may cause damage.

3.Before use, ensure screws/nuts are properly tightened and the propeller is securely mounted.

4.Before takeoff, check the tightness of all mounting screws/nuts and the integrity of the propeller. Propellers are non-repairable consumables. Discontinue use immediately if any cracks are found, as they pose a fracture risk.

5.Strictly adhere to the operating temperature range: -30°C to 60°C.

6.Storage Conditions: Store away from corrosive gases and harmful environments. Ideal storage temperature is 10°C-35°C with humidity not exceeding 65%. For long-term storage, please pay special attention to these conditions.

7.Please use this product in compliance with all local laws and regulations.

Copyright © 2003-2023 T-motor, All rights reserved.