VZ SERIES

-VTOL PROPELLERS

Break through the performance limitations of traditional multi-rotor propellers. VZ series propellers deliver superior power, durability, and lightweight design for VTOL applications

What Does

a VTOL Propeller Need?

High Strength High Stiffness & Lightweight Design

High Strength

Withstands immense centrifugal loads and maneuver-induced alternating loads at high RPM, preventing structural failure

High Stiffness

Ensures safe blade-tip clearance in compact layouts, suppresses aeroelastic deformation, and prevents flutter

Lightweight Design

Reduce the moment of inertia to achieve rapid thrust response and higher attitude control bandwidth for the flight control system

Superior Aerodynamic

Design

The unique dual operational modes of VTOL—vertical takeoff/landing and cruise—demand new propeller capabilities

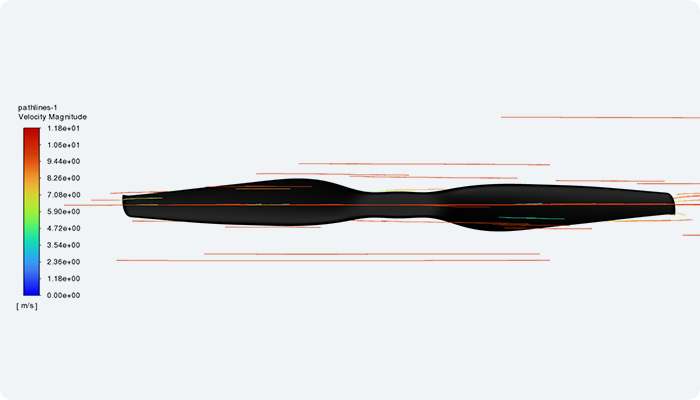

Vertical Takeoff &

Landing Phase

Requiring high thrust and power, demanding maximum lift output from the propeller disk within a limited blade area

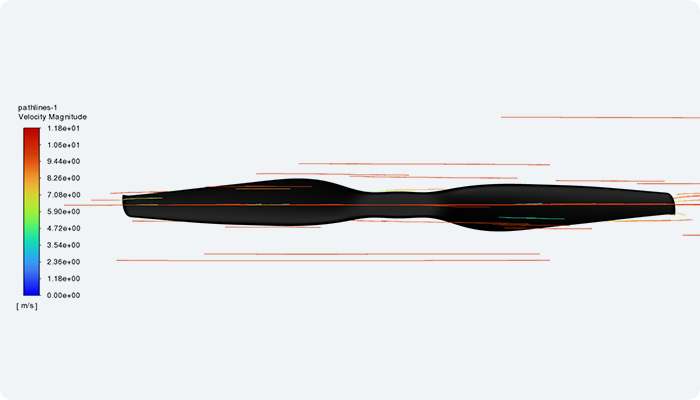

Cruise Phase

When the propeller stops rotating, it is necessary to minimize profile drag to reduce power consumption, achieving "stealthy" low-drag efficiency

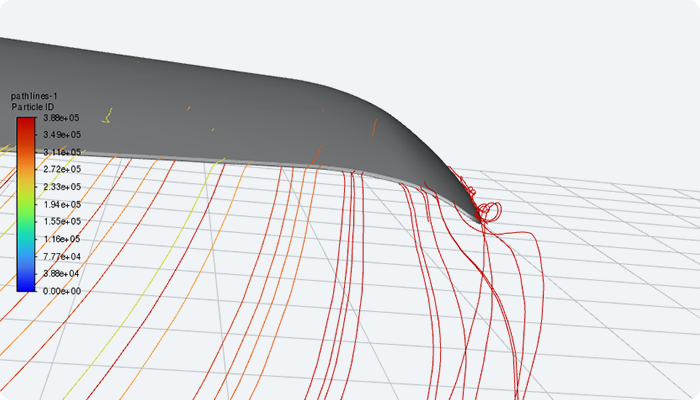

Transition Stability:

Resisting Complex Flow

Field Interference

The extreme challenges posed by high angle of attack, low speed and unsteady flow field, coupled with the insufficient strength and poor transition stability of traditional blades, make this an accident-prone region

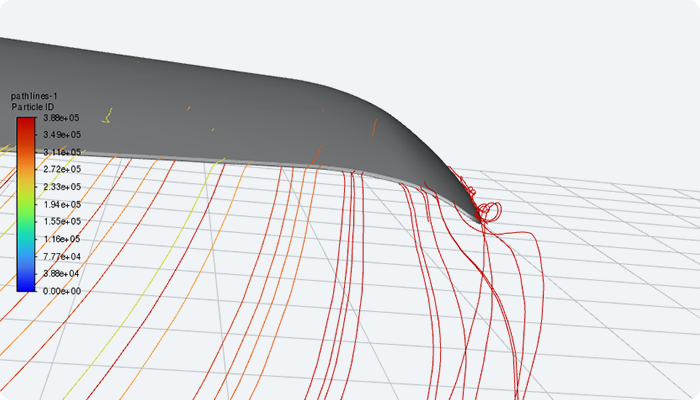

Unsteady Flow Fields

at High Angle of Attack

The aircraft operates at high angles of attack and low speeds within an extremely complex flow environment

Asymmetric Airflow

Significant angle between incoming flow and the rotation axis causes asymmetric airflow entering the propeller disc

Severe Periodic

Variations

Local forces on the blade fluctuate drastically per rotation, inducing flutter and causing significant thrust fluctuation

To address the challenges of traditional propellers in VTOL (Vertical Takeoff and Landing mode) applications

we introduce the VZ Series Propellers

Technical Features of the VZ Series Propellers

Advanced composite materials and exceptional aerodynamic design work in synergy to ensure consistently efficient, reliable, and controllable power output

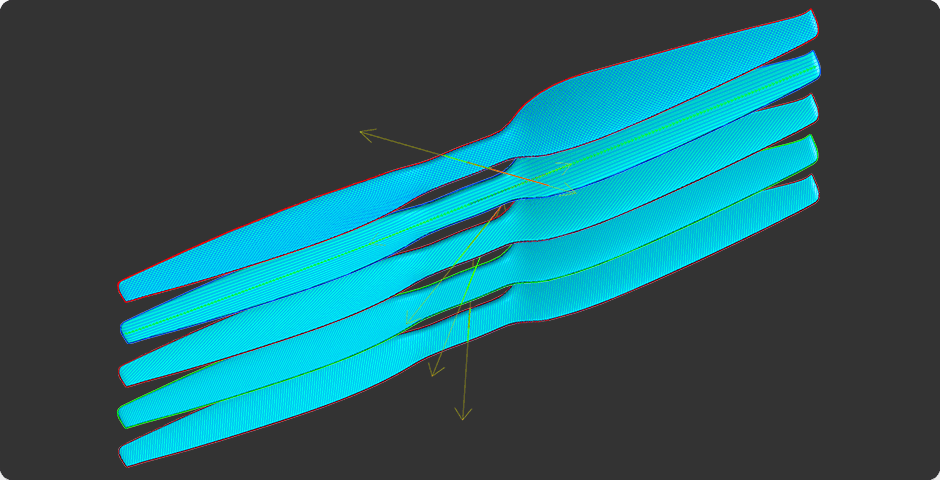

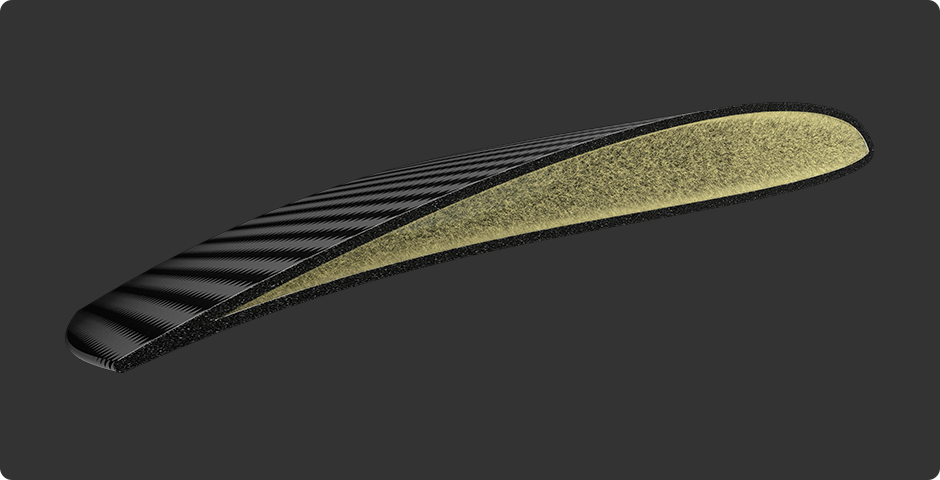

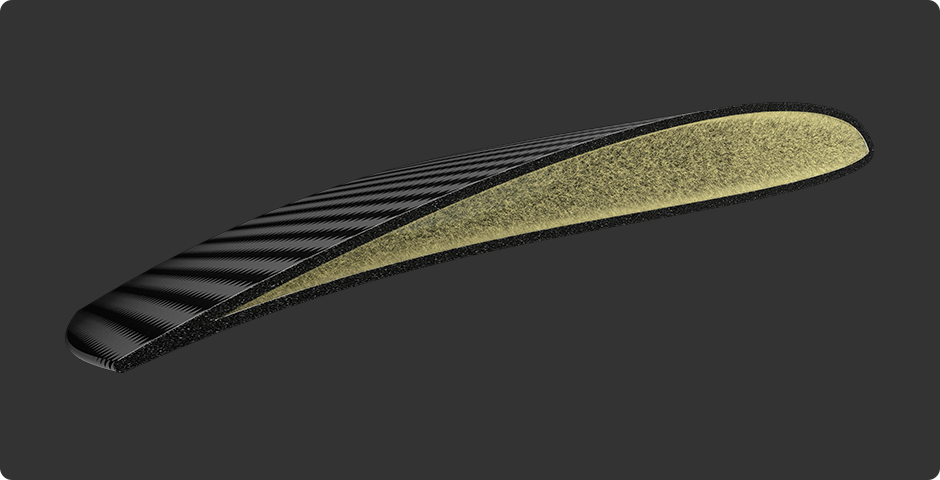

Bending & Torsion Resistant Layup Design

Optimized fiber orientation and ratio maximize strength and stiffness

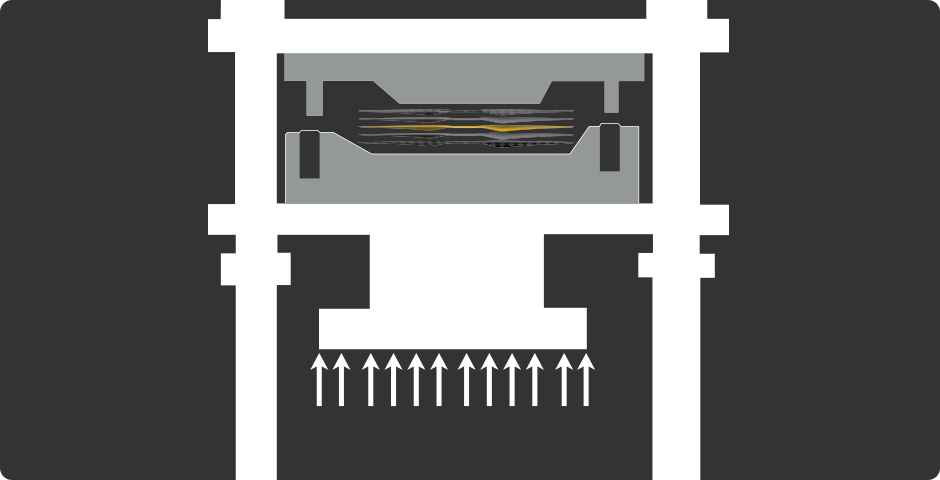

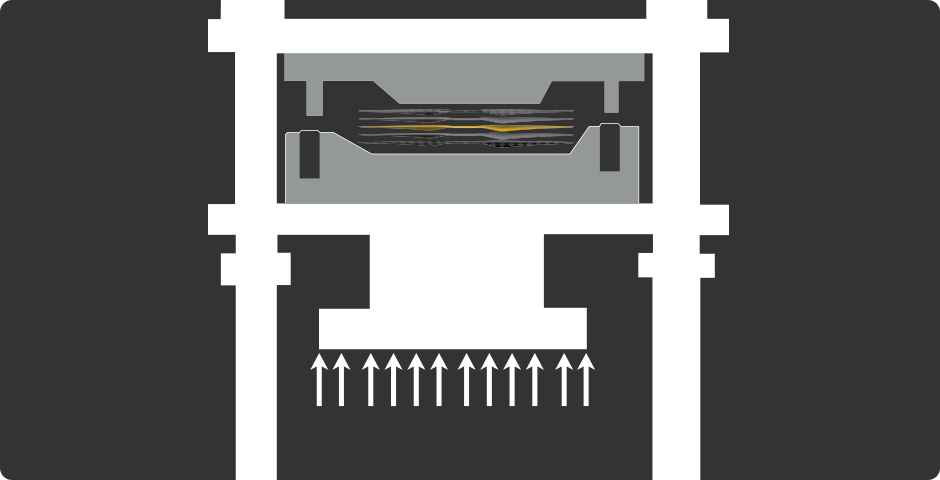

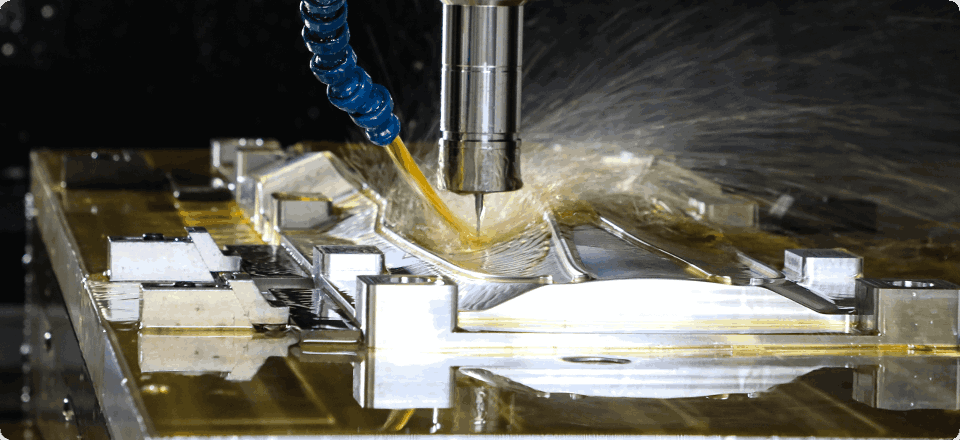

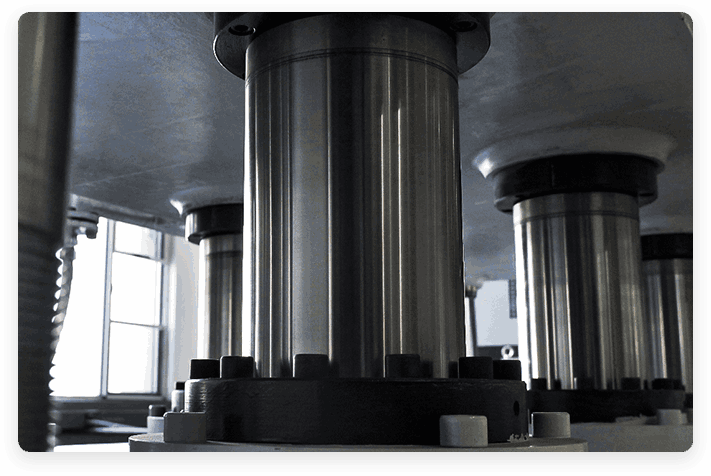

Prepreg Compression Molding for Integrated Forming

Product porosity below 1%, ensuring stable and reliable quality

PMI Foam Core

Lightweight, high-strength core material effectively increases stiffness while controlling total weight

30%

Flexural Strength

Significantly enhanced impact resistance and deformation resistance for greater durability in complex operating conditions

20%

Torsional Stiffness

Optimized power transmission efficiency reduces energy loss during operation

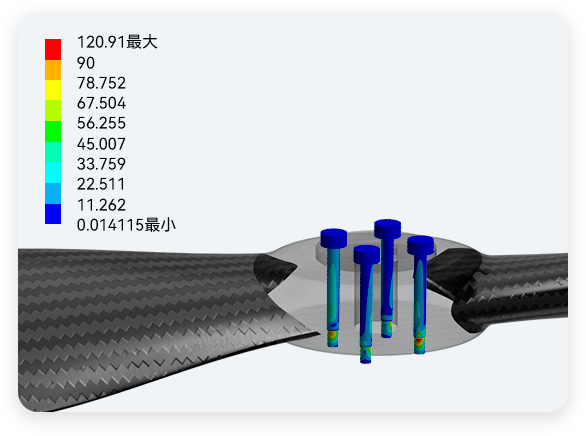

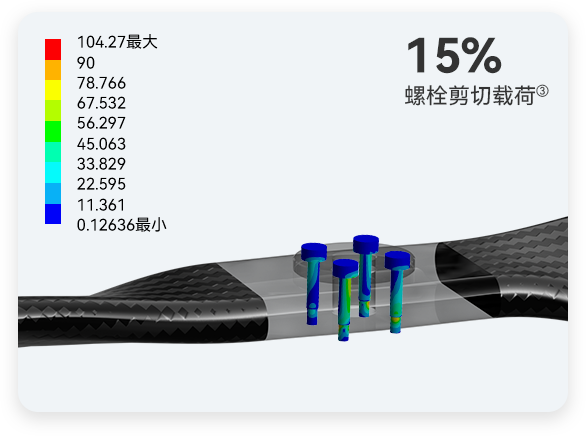

Blade Root Optimization:

Safety Redundancy Design

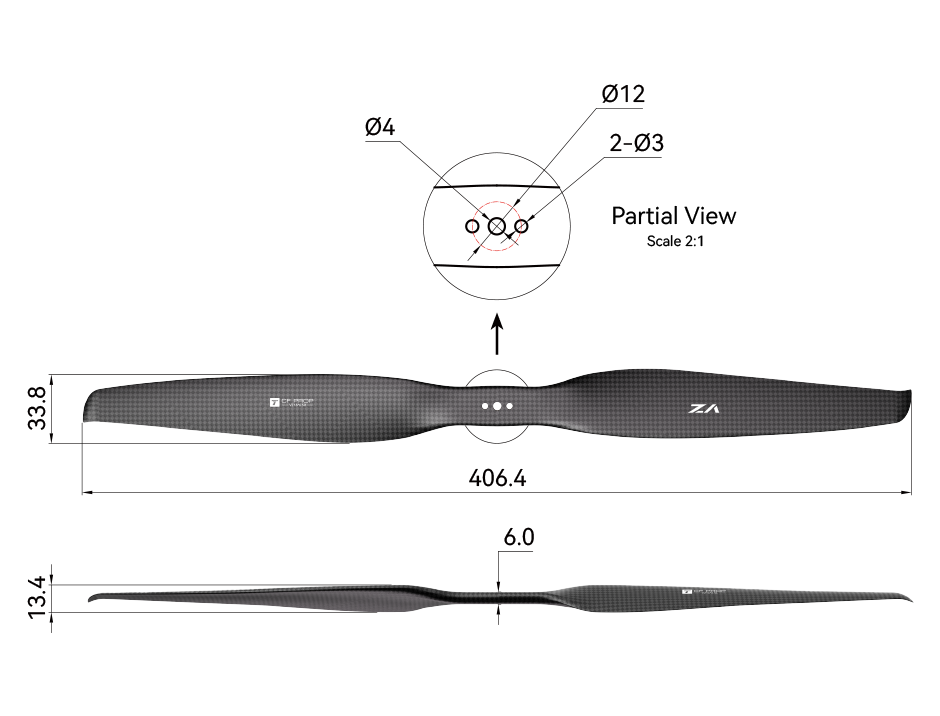

The blade root thickness is optimized to provide structural redundancy while reducing loads on the connecting bolts

V30 Propeller

VZ30 Propeller

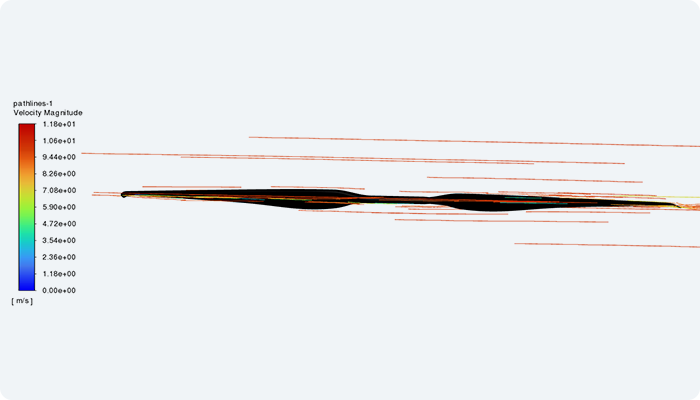

Aerodynamic Priority:

Engineered for High VTOL Thrust

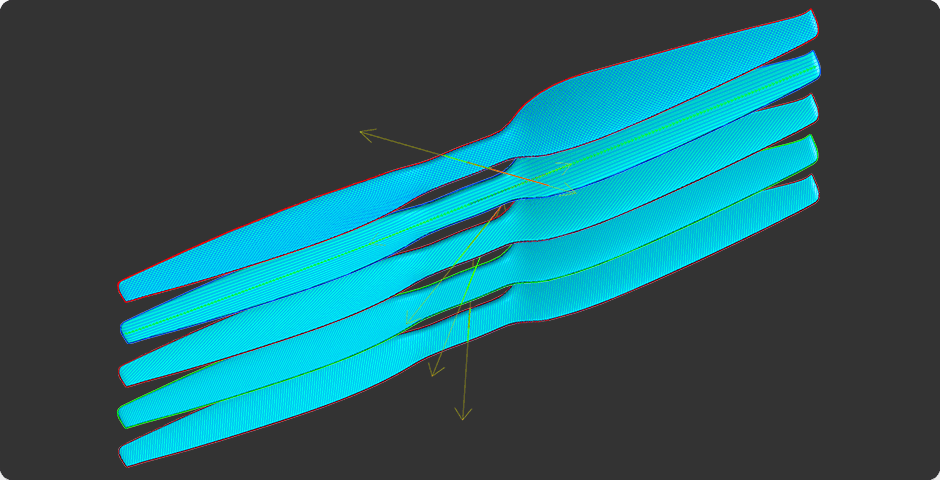

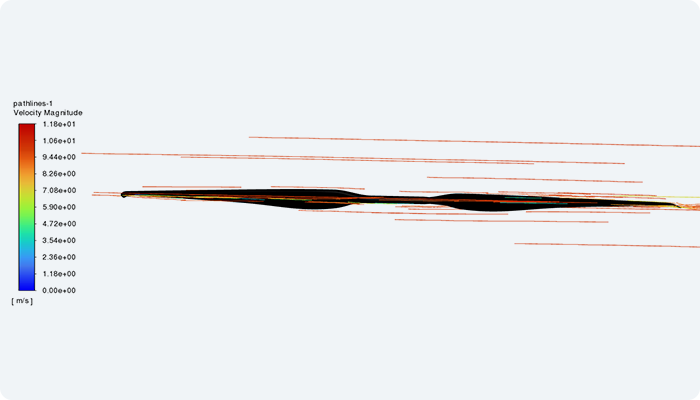

Dedicated High Lift-to- Drag Ratio Airfoil

Optimized for VTOL conditions to enhance maximum lift coefficient

Low-Drag Cruise Blade Shape

Improved aerodynamic blade boundaries reduce cruise drag

Specialized Blade Tip

Optimized tip design weakens vortex strength and enhances flight quality

Dedicated High Lift-to- Drag Ratio Airfoil

Optimized for VTOL conditions to enhance maximum lift coefficient

Low-Drag Cruise Blade Shape

Improved aerodynamic blade boundaries reduce cruise drag

Specialized Blade Tip

Optimized tip design weakens vortex strength and enhances flight quality

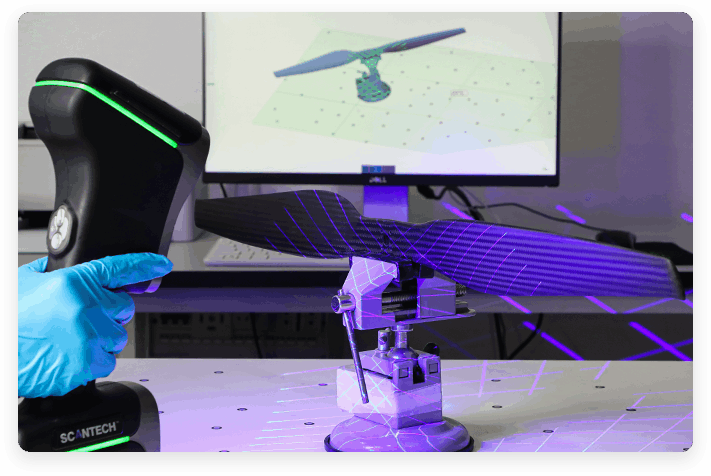

Custom VTOL Propeller Service: 10 to 100 Inches

Supports precise matching with various pitch specifications and motors Full in-house R&D ensures stable and controllable quality

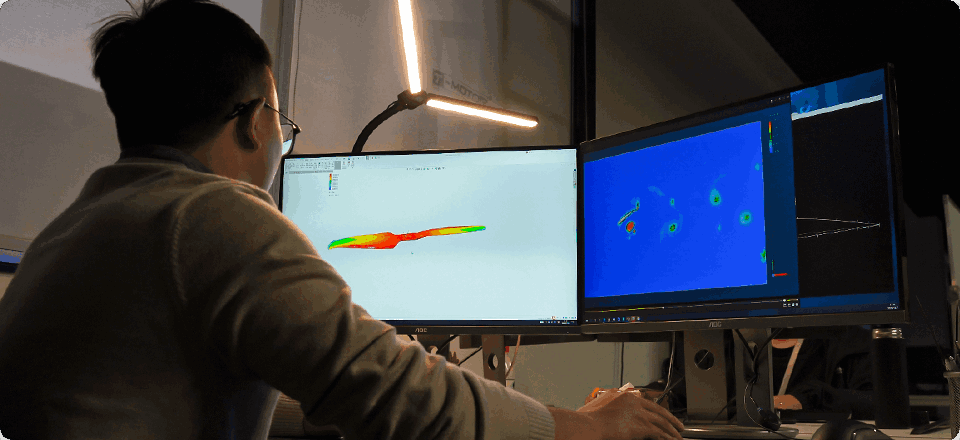

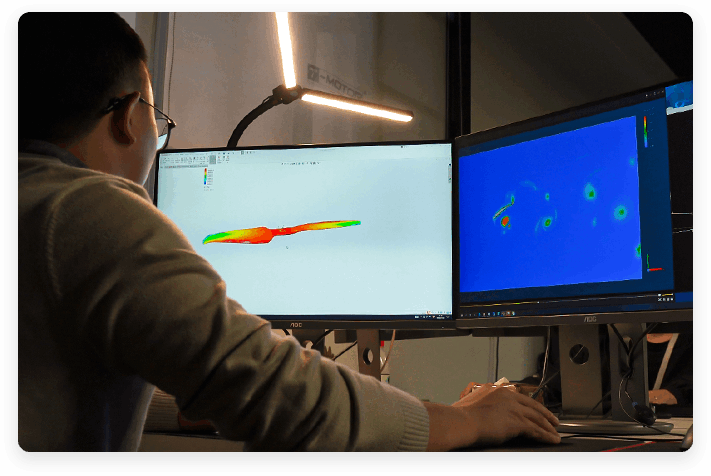

Aerodynamic/Structural Design

Mold Manufacturing

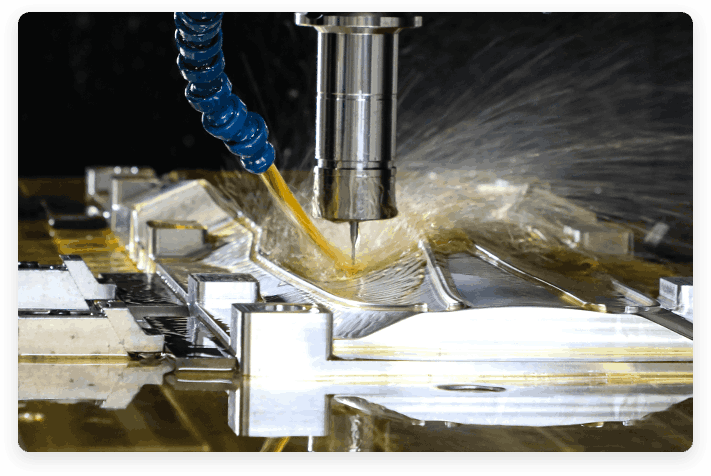

Composite Molding

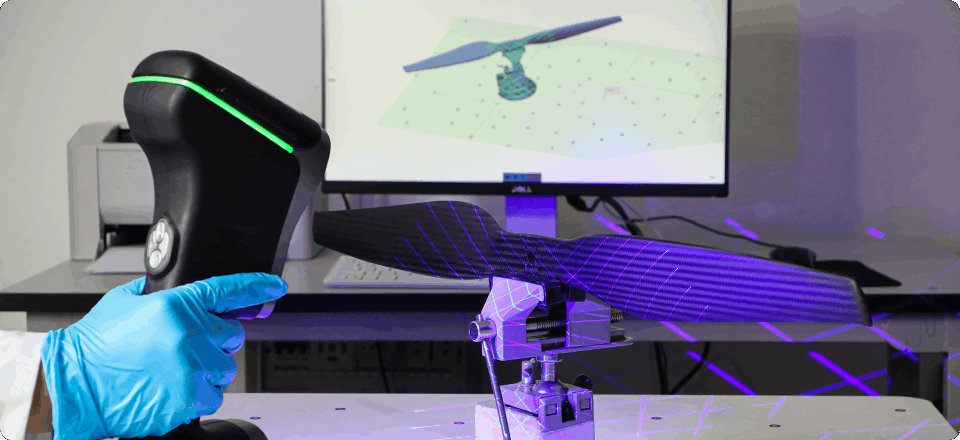

Testing & Validation

① The appearance diagrams and product renderings in this document are for reference only; the actual product shall prevail.

② Data regarding improvements in flexural strength and torsional stiffness are derived from comparative testing between the VZ Series propeller and the G Series propellers.

③ Data regarding the reduction in bolt shear load is sourced from simulation comparisons between the installation bolts for the VZ Series propellers and those for the V Series propellers.

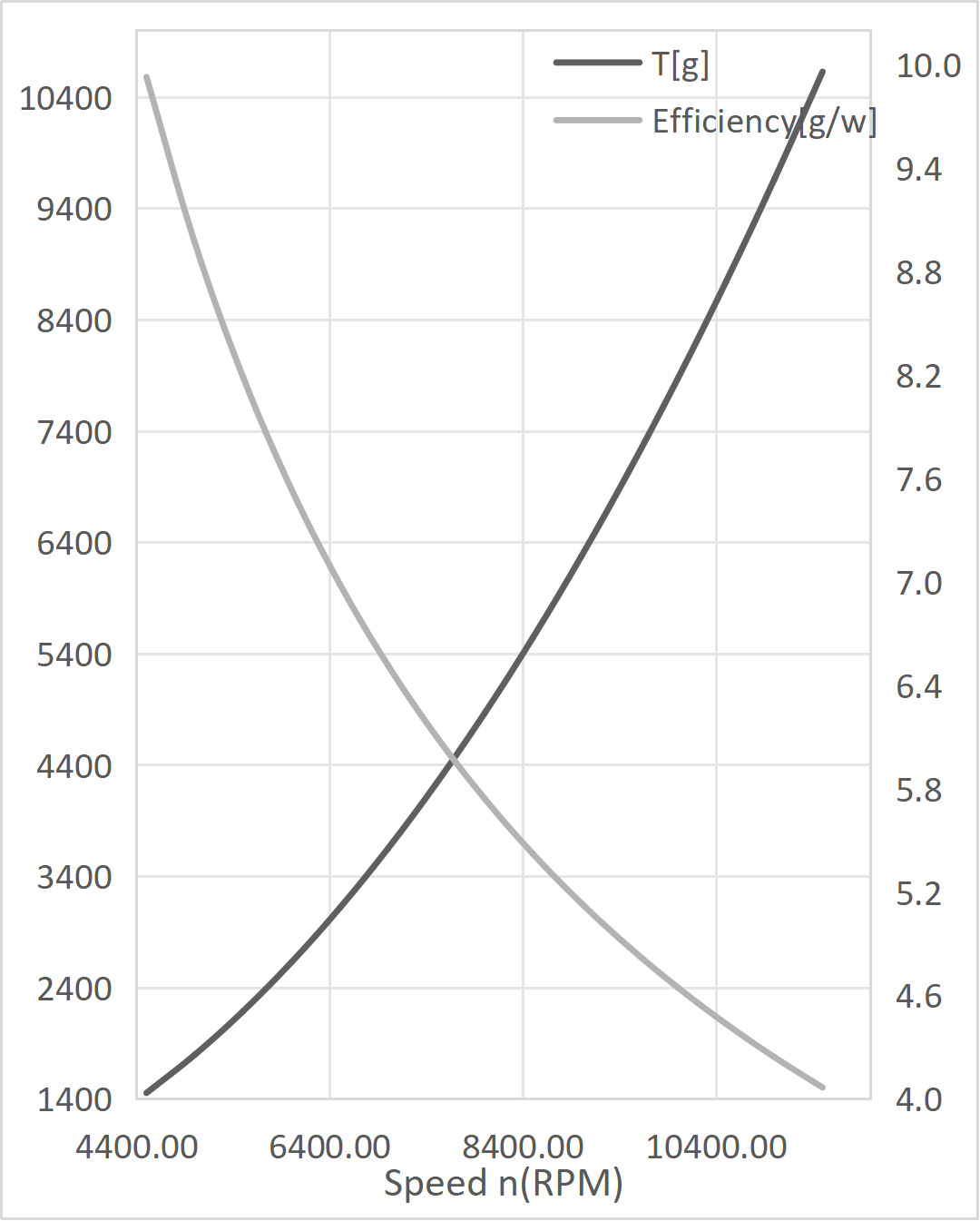

④ The test data presented above were obtained under specific conditions, using equipment within our company's laboratory. Actual data and parameters may vary slightly depending on the test environment, platform, software, and other factors.